Intellectual Capital

Our innovative solutions have propelled us to become a commercial powerhouse in India. Deeply committed to nurturing a culture of innovation, we are well-prepared for the future, to generate a sustainable value for all those involved in our endeavours. We aspire to harness our intellectual prowess to drive significant advancements and contribute to the prosperity of both, the Company, and the communities we serve.

Innovations in Processes and Products for a Resilient Future

Our advancement is deeply rooted in the potency of our intellectual capital. Our dedication revolves around developing and constantly shaping top-notch products and services driven by a robust culture of modernisation. Intellectual capital embodies the intangible assets stemming from knowledge, encompassing our Company’s proficiency, methodologies, and systems. Through innovation, we enhance the calibre, sustainability, and enduring growth prospects of our wide array of products and enterprises.

Key Highlights for the Year

-

New Projects/Products Launched: 4

SDG Linkages

Key Material Topics Under Social and Relationship Capital:

-

Customer Experience and Satisfaction

-

Brand Management

Linkages with NGRBC Principle:

-

Principle 2

-

Principle 6

-

Principle 9

Linkages with other capitals:

Financial Capital: Nurturing intellectual capital enhances a culture of innovation, fuelling revenue growth and fostering the expansion of financial capital.

Natural Capital: Investing in intellectual capital champions sustainable practices, optimising resource utilisation, and safeguarding the environment, thus enhancing natural capital for the benefit of future generations.

Social and Relationship Capital: Intellectual capital serves as a catalyst for addressing social challenges through innovative solutions, fostering meaningful relationships, and changing communities.

Human Capital: Strategic investment in intellectual capital cultivates employee knowledge and expertise, building a culture of innovative thinking and empowering effective problem-solving, driving continuous development and enriching human capital.

Manufactured Capital: Leveraging intellectual capital propels the optimisation of manufacturing processes, resulting in heightened efficiency and cost reduction. This strategic approach enhances productivity amplifying the value creation of manufactured capital, thus fortifying competitive edge and market resilience.

In a world where change is the only constant, we embrace innovation as the vital lifeline of our business. It is the catalyst that transforms challenges into opportunities and ideas into reality.

At CTIL, our dedicated teams, with their diverse expertise, are the bedrock for our innovative endeavours. They bring forth groundbreaking ideas that redefine industry standards and set new benchmarks.

Key Enablers of Our Innovative Spirit

Our commitment to Research and Development (R&D) stands as a testament to our beliefs in the power of intellectual capital. With significant investments in R&D, we have established state-of-art facilities that serve as the breeding ground for creativity and technological breakthroughs. Our intellectual capital is not just a resource, it is the engine that drives our product design, process optimisation, and technological advancements.

Commitment to R&D

Significant Investments

Breeding Ground for Innovation

Driving Product Design

Optimising Processes

Advancing Technology

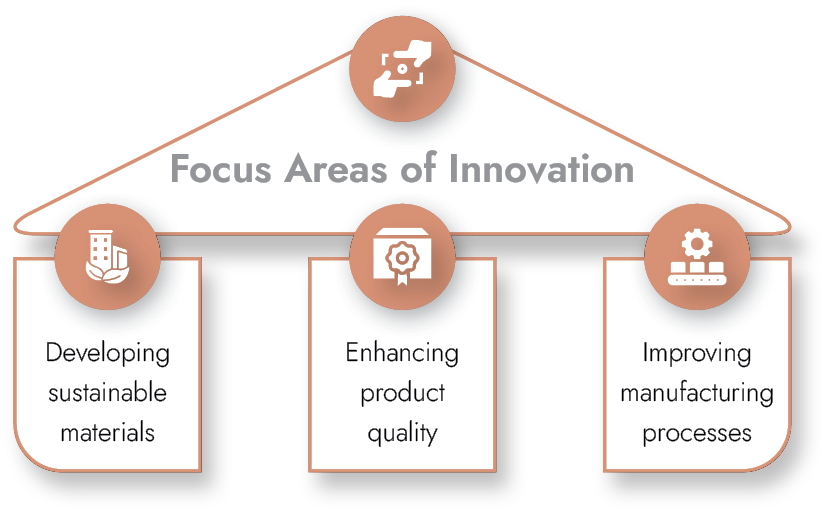

We prioritise key areas of focus, namely, ‘Developing sustainable materials’, ‘Enhancing product quality’ and ‘Improving manufacturing processes’ which are aimed at driving sustainable growth and societal impact. Central to our innovation agenda is the development of sustainable materials.

Our commitment to R&D is evident in our consistent efforts to push the boundaries of what is possible. We strategically leverage our intellectual property, including patents and trademarks, to carve out a competitive edge in the global marketplace. Our portfolio of intellectual assets reflects our pioneering spirit and commitment to maintaining our position as industry leaders.

We encourage innovation by fostering a culture of risk-taking, collaboration, and continuous learning. We believe that every employee has the potential to contribute to our innovative journey, and we empower them with the tools and freedom to explore new horizons.

Empowering Innovation for Positive Transformation

REAL ESTATE

Innovation is the lifeblood of our business. It’s what allows us to create not just buildings, but communities that stand the test of time. Our focus on integrating the latest technology and continuous innovation ensures that we are not just part of the industry’s evolution; we are at the forefront, leading it.

- K. T. Jithendran, MD-CEO,

Birla Estates Pvt. Ltd. (BEPL)

Our Real Estate segment is pushing the frontiers of the industry forward to encourage innovation and intellectual capital. Propelled by CTIL’s legacy that spans over a century, our Real Estate segment has consistently been at the helm of integrating cutting-edge technologies and sustainable practices into our business model.

Innovation is driven by a steadfast dedication to enhance customer experiences and creating value at every level. Our innovative spirit is fuelled by the LifeDesigned® philosophy, which ensures that every project is crafted to cater to the evolving needs of our customers. This philosophy is not just a guiding principle, but a tangible reality in our projects, where thoughtful designs, landscaped green spaces, lifestyle amenities, and environmental consciousness come together to create harmonious living spaces.

The key focus areas for innovation include sustainable development, smart city applications, and offsite construction. By leveraging Artificial Intelligence (AI) and the Internet of Things (IoT), we are exploring new frontiers in smart building applications and are working towards transforming its commercial offices into smart spaces. We do not just aim to build properties; we aim to craft ecosystems that stand as a testament to the power of innovation.

Advancing Building Construction through Concrete Sensor Innovation:

Problem

A significant challenge faced by the Real Estate segment is the effective monitoring of properties and conditions within building structures through the construction lifecycle. Traditional methods of concrete strength testing, such as cube or cylinder testing, are laborious, time-intensive, and provide sporadic data, leading to variability and potential inefficiencies in decision-making.

Solution

The segment has embarked on a transformative journey by introducing cutting-edge concrete sensor technology. By embedding state-of-the-art sensors directly into concrete structures, we are pioneering a new era of construction management. The sensors enable the real-time monitoring of concrete maturity is a key indicator of in-place strength development.

Unlike traditional methods that rely on labour-intensive cube or cylinder testing, this approach leverages the principle of concrete hydration temperature history to estimate real-time strength accurately.

The adoption of wireless sensors presents several distinct advantages. These are,

-

Data is continuously logged and retrieved in real-time, eliminating the variability associated with intermittent cube or cylinder testing. This consistency ensures more reliable results and enables proactive decision-making during construction.

-

The maturity method provides a predictive insight into the actual in-place strength of concrete, offering invaluable benefits for optimising concrete mixes and reducing construction cycle times.

With sufficient data from these sensors, we can refine concrete compositions, optimise costs, and streamline project timelines based on real-time strength assessments. To validate the efficacy of the sensor technology, we also conduct comparative studies by placing maturity sensors alongside traditional cube or cylinder testing. This approach provides tangible evidence of sensor accuracy and reliability, enhancing confidence in our innovative methods.

Benefits

-

Real-time Monitoring:

Concrete sensors offer real-time data on crucial parameters like temperature and humidity, facilitating proactive monitoring and immediate response during construction.

-

Lifecycle Management:

These sensors play a vital role in long-term management beyond construction, monitoring environmental conditions and structural integrity for proactive maintenance, thereby extending the lifespan of buildings and infrastructure.

-

Precision Engineering:

Leveraging concrete sensors enables precise engineering in construction projects by optimising concrete mixtures and curing processes based on real-time data insights, enhancing material usage and overall quality.

-

Data-driven Decision Making:

Concrete sensors empower informed decisions at every stage of the construction life cycle through the collection of valuable data, optimising schedules and predicting maintenance needs to enhance efficiency and productivity across projects.

Delivering Customer Experience through Proptech Tools

The Real Estate segment leverages digital technology to elevate customer experiences across all facets of the offerings. Through the integration of Proptech tools, customers come closer to their dream properties, offering immersive virtual tours and cutting-edge digital experiences.

The integration of digital technology not only sets new standards for customer experience in the real estate industry but also demonstrates a commitment to innovation and excellence in every aspect of its offerings.

Dwell App

- Modern living gateway

- User-friendly, feature-rich

- Empowers residents and professionals

VR & AR Technologies

- 360° virtual property tours

- Detailed interior and safety features

My Home App

- Digital homeownership hub

- Enhances homeowner journey

- Connects and informs users

360° Walkthroughs & Matterport Tours

- Global home experience

- Interactive, multi-device support

Photorealistic Displays

- Unreal Engine 4 visuals

- Real-time apartment views

- Comprehensive project exploration

Curved LED Wall Experience

- Immersive Birla Niyaara centre

- Lifelike home previews

Gen-AI in Marketing

- Innovative campaign tools

- Social media and digital targeting

- Smooth customer handover process

PULP AND PAPER

As global markets evolve towards intricate structures and competition intensifies in creating sustainable products, the Pulp and Paper sector remains committed to continuous innovation and aligning its core business values with sustainability.

- R.K. Dalmia, MD,

Century Textiles Industries Limited (CTIL)

With a rich history dating back to 1984, our dedication to innovation is woven into the fabric of our operations, driving us to explore new frontiers in product design, process optimisation, and technological advancements. Our innovation strategy is centred around sustainability, cost-effectiveness, and quality. We are committed to developing sustainable, bio-degradable, and eco-friendly products that meet the highest standards of quality and hygiene. By leveraging our intellectual capital, we aim to enhance our manufacturing processes.

We foster a culture of innovation by investing in research and development (R&D) and embracing cutting-edge technologies. We have invested in new technologies and machinery to double our tissue paper production and have developed several alternatives to plastic for manufacturing eco-friendly tableware items. This commitment to innovation has allowed us to replace old products with new, innovative offerings, giving us a competitive edge in the market.

Innovative Products Launched in FY 2023-24

Carrier Tissue (Water-based coating)

Oil and Grease Resistance (OGR) Paper

Brown carrier tissue

Ultra-soft tissue

Cigarette boards

Straw paper

A significant milestone for us is the development of ‘Century Green Pulp’, crafted from bagasse utilising advanced moulding technology. This innovative green pulp serves as the foundation for crafting biodegradable tableware items notably, adhering to stringent Food and Drug Administration (FDA) regulations, aligning with the guidelines set forth by the Food Safety and Standards Authority of India (FSSAI) for food packaging, ensuring both sustainability and safety in our offerings.

Green Innovation: Proficient Wastewater Management to Generate Clean Energy

Problem

The Pulp and Paper segment faces challenges in managing high Chemical Oxygen Demand (COD) wastewater effectively leading to environmental concerns and resource wastage. Conventional wastewater treatment methods often fall short in addressing these issues, resulting in increased operational costs and environmental impact.

Solution

An innovative green technology, utilising the Upflow Anaerobic Sludge Blanket (UASB) process, has been introduced to convert high COD wastewater into valuable biogas, primarily composed of methane. This biogas is further upgraded into Compressed Methane Gas (CMG) through Caustic and Water Scrubbing processes, making it suitable for use as a substitute for Liquefied Petroleum Gas (LPG) in tissue paper plants.

Wastewater Treatment using Upflow Anaerobic Sludge Blanket (UASB) Process:

-

The high COD wastewater from the Pulp and Paper segment is treated using the UASB process.

-

In this anaerobic treatment method, wastewater flows upwards through a bed of anaerobic sludge where microorganisms break down organic pollutants, converting them into biogas.

-

Methane (CH4) is the primary component of the biogas produced in this process.

Biogas Upgradation to Compressed Methane Gas (CMG):

-

The biogas obtained from the UASB process is upgraded to CMG with a methane concentration of 95%.

-

This upgradation is achieved through Caustic and Water Scrubbing:

Caustic Scrubbing:

The biogas is passed through a caustic solution (sodium hydroxide) to remove acidic gases like CO2 and H2S.

Water Scrubbing:

Further purification is done by passing the gas through water to remove remaining impurities and moisture.

Utilisation of CMG:

The purified CMG, now predominantly methane, is then suitable for use as a replacement for Liquefied Petroleum Gas (LPG) in tissue paper manufacturing processes within the plant.

CMG serves as a clean and sustainable energy source, reducing dependence on conventional fossil fuels like LPG and contributing to environmental sustainability.

Benefits

-

Efficient Wastewater Treatment:

The UASB process efficiently treats high COD wastewater, utilising anaerobic microorganisms to convert organic pollutants into biogas, addressing environmental concerns and regulatory compliances.

-

Clean Energy Generation:

Biogas produced from wastewater treatment serves as a valuable energy resource, reducing dependence on conventional fossil fuels like LPG and contributing to environmental sustainability.

-

Resource Optimisation:

The conversion of wastewater into biogas and CMG promotes circular economy principles, minimising waste generation and maximising resource utilisation within the pulp and paper production process.

-

Environmental Footprint Reduction:

By utilising CMG as a clean and sustainable energy source, the overall environmental footprint of pulp and paper production is reduced, aligning with corporate sustainability goals and regulatory requirements.

Innovatively Leveraging Precipitated Calcium Carbonate for Sustainable Gains:

Problem Statement:

Our Pulp and Paper segment faces challenges related to resource management and environmental impact within our operations. Traditional methods rely heavily on wood pulp, leading to increased energy consumption and emissions associated with pulp production. Additionally, the reliance on external sources for filler materials adds logistical complexities and environmental strain.

Solution

To address these challenges, we established an on-site Precipitated Calcium Carbonate (PCC) production facility, showcasing profound intellectual capital in resource management and environmental stewardship. This strategic adoption of PCC optimises paper quality, enhances mill competitiveness, and significantly reduces reliance on wood pulp and energy, while minimising emissions associated with pulp production.

Benefits

-

Environmental Impact Reduction:

On-site PCC production directly improves air quality by curbing particulate, sulfur dioxide, and carbon dioxide emissions. Each ton of PCC absorbs approximately 440 kgs of CO2 during its production, contributing to carbon footprint reduction.

-

Efficient Resource Utilisation:

Integration of PCC within the paper mill’s operations minimises reliance on external filler materials, reducing logistical complexities and environmental impact associated with transportation. This approach fosters economic benefits within the local community and reduces operational costs for CTIL.

-

Wastewater Treatment Enhancement:

The strategic use of PCC within the paper manufacturing process facilitates efficient solid by product utilisation and minimises organic load (BOD/COD) in wastewater treatment, contributing to environmental sustainability and regulatory compliance.

-

Operational Efficiency and Competitiveness:

Seamless integration of PCC enhances paper quality, whiteness, opacity, and consistency, driving operational efficiency and enhancing mill competitiveness in the market.

Way Forward

Moving forward, at CTIL we remain committed to driving growth and excellence through innovation. By continuing to prioritise R&D, inculcating a culture of collaboration, and embracing new technologies, we aim to maintain our position as a commercial powerhouse while making significant strides towards sustainability and societal impact. We continue to invest in empowering each team member to contribute their unique insights and expertise towards our collective success. With a focus on developing sustainable materials, enhancing product quality, and improving manufacturing processes, we seek to set new benchmarks of excellence and environmental stewardship in the industries we operate in. Through ongoing innovation and a strong adherence to our core values, we are confident that we are poised to lead positive transformation in the ever-evolving landscape of business and technology.