Manufactured Capital

Manufactured capital forms the operational backbone of our performance. It encompasses our tangible assets and infrastructure, including our strategically located production facilities equipped with advanced machinery and technology, all optimised for efficiency and sustainability. We continuously invest in technological infrastructure, including automation and digitisation solutions, to ensure enhanced productivity and operational efficiency.

Our efficient supply chain management and adherence to stringent quality control measures are facilitated by our manufactured capital, enabling us to maintain high-quality standards while minimising environmental impact.

In essence, CTIL's manufactured capital is central to driving our operational excellence, maintaining our competitive advantage, and delivering sustainable value to our stakeholders.

Empowering Sustainability: Pioneering Manufacturing Innovations for a Better Tomorrow

Our Real Estate segment, anchored in CTIL's 125-year-old rich legacy, specialises in the development of premium and mid-income residential housing. We are committed to excellence, collaborating with top-tier construction partners, architects, and suppliers to ensure best-in-class developments. In our Pulp and Paper segment, state-of-the-art manufacturing facilities exemplify our success in meeting diverse customer demands. These facilities support our continuously expanding product portfolio and growing client base, both domestically and internationally. We cater to customer needs with our advanced production capabilities and sustainable operations. Furthering our commitment, we invest in cutting-edge manufacturing plants and equipment, utilising non-toxic chemicals and eco-friendly processes to deliver superior services to our consumers.

Key Highlights

Real Estate

Real Estate Development:

6 Residential Projects 2 Commercial Projects

Area under construction:

9.3 million sq. ft.

GRESB Ratings:

91/100 - Development (Residential) (12.30% improvement YoY)

80/100 - Standing Investment (Commercial) (23.07% improvement YoY)

Pulp and Paper

Manufacturing Capacity: 4,81,130 tonnes per annum

Capacity Utilisation: 97%

Innovative and Eco-Friendly Products:

-

Tissue offering expansion to include brown tissues and ultra-soft tissues

-

Foray into Oil and Grease-resistant (OGR) paper, brown craft paper

SDG Linkages

Key Material Topics Under Manufactured Capital

-

Occupational Health and Safety

-

ESG Incident and Risk Management

-

Customer Experience and Satisfaction

-

Brand Management

-

Energy and Emissions Management

-

Water and Wastewater Management

-

Waste Management

Linkages with NGRBC Principle:

- Principle 2

- Principle 6

- Principle 9

Linkages with other Capitals:

Human Capital: Our strong and resilient workforce breathes life into manufactured capital, unlocking its full potential and driving our Company's success. Investing in training programmes equips our workforce with the skills needed to effectively utilise the manufactured capital.

Financial Capital: Consistent investment in production and construction processes ensures a stable financial foundation for our operations.

Natural Capital: We are responsible for a balanced consumption of resources and managing our natural capital with environmental sustainability in mind for real estate construction, and paper production.

Intellectual Capital: Exploring and implementing innovative practices and technologies to upgrade our manufacturing processes, fostering a culture of continuous improvement, and staying ahead in the industry.

Real Estate Construction and Development

Dedicated to excellence, we steadfastly uphold our commitment to deliver high-quality residential and commercial properties. Our approach distinguishes us in the industry, as we focus on efficient design, a customer-centric philosophy, impeccable quality, and the seamless integration of sustainability with cutting-edge technologies. We are actively engaged in expanding our comprehensive project portfolio through detailed strategic planning and market analysis.

Ongoing and Completed Projects

Residential

Birla Vanya

Kalyan Maharashtra

13.3 lakhs Sq. Ft Area under development

Birla Navya

Golf Course Extension, Gurugram, NCR

18.5 lakhs Sq. Ft Area under development

Birla Niyaara (P1 & P2)

Worli, Mumbai

24.8 lakhs Sq. ft Area under development

Birla Alokya

Whitefield, Bengaluru

5.5 lakhs Sq. Ft Area under development

Birla Tisya

Rajajinagar, Bengaluru

6.5 lakhs Sq. Ft Area under development

Birla Trimaya

Rajajinagar, Bengaluru

36.2 lakhs Sq. Ft Area under development

Commercial

Birla Centurion

Worli, Mumbai

3.5 lakhs Sq. Ft A Operational

Birla Aurora

Worli, Mumbai

2.6 lakhs Sq. F Operational

Upcoming Projects with Development Potential

Residential

Walkeshwar

South Mumbai

0.6 lakh sq. ft

Hindalco

Thane

53.9 lakh sq. ft

RR Nagar

South-West, Bengaluru

10.1 lakh sq. ft

Sarjapur

South-East, Bengaluru

28.7 lakh sq. ft

Wellesley Road

Pune

16.2 lakh sq. ft

IHP,

Mathura Road

14.3 lakh sq. ft

Birla Navya (P3)

NCR

6.8 lakh sq. ft

Birla Trimaya (P2 & P3)

Rajajinagar, Bengaluru

29.0 lakh sq. ft

Being actively involved in strategic planning, we identify and develop properties in prime locations, focussing on the mid-premium to ultra-luxury segment, which constitutes nearly half of India's real estate market.

Our activities range from land identification and acquisition to sales and facilities management. Currently, our strategic expansion prioritises residential properties in key urban centres such as National Capital Region (NCR), Mumbai Metropolitan Region (MMR), Bengaluru, and Pune; cities that represent about two-thirds of India's residential real estate sector. This targeted approach allows us to deepen our presence in key cities. We maximise our impact by delivering exceptional designs and amenities tailored to the evolving needs of discerning customers thereby setting new benchmarks in the real estate industry. Our legacy of quality and sustainability propels us to provide an iconic brand experience that resonates with our values and customer expectations.

Our Focus Areas

Customer Centricity

Ensuring Quality

Integrating Sustainability

Design

Next Level Living: Powered by Technology

Our Real Estate segment is strategically focused on five pivotal areas, namely Customer Centricity, Design, Quality, Technology and Sustainability. These collectively drive our commitment to excellence and innovation.

Design excellence and sustainable innovation are pivotal to our approach at Real Estate Segment of CTIL. We are dedicated to enhancing the user experience with our residential and commercial projects that not only showcase signature aesthetics but also incorporate environment-friendly features. Our guiding design philosophy, LifeDesigned®, draws from deep insights into the lifestyles and aspirations of our customers, ensuring that each project is a nurturing space that enriches lives.

LifeDesigned® transcends traditional architecture by integrating innovative practices with practical sustainability. We collaborate with a diverse team of experts, each contributes with their unique perspectives that breathe life into our vision.

Our commitment to this philosophy is evident across all our projects, each designed to be a benchmark in architectural excellence. By pushing the boundaries of design and functionality, we ensure that every structure is not only a place to live but a space that is alive with potential and promise for the future.

In our Real Estate segment, maintaining the highest quality standards is paramount to exceeding customer expectations. This commitment is deeply ingrained in every facet of our operations, from meticulous design and precision in construction to unmatched customer service and continued support.

Quality for us transcends meeting technical specifications; it involves delivering exceptional value that enhances the living experiences of our customers. To uphold these standards, we have instituted a comprehensive quality management system that scrutinises all operational aspects. This system ensures that every process is efficient, effective, and continuously improved upon to align with our strategic objectives of delivering high quality products and services.

By rigorously assessing and refining our procedures, we not only meet, but aim to surpass the expectations set by our customers, to build lasting trust. This ongoing pursuit of excellence defines our journey towards creating spaces that are not just built but are crafted with precision and consideration.

Using Wireless Maturity Sensors to Determine Concrete Quality during Construction

In the construction sector, accurately assessing the compressive strength of concrete is crucial for the integrity and longevity of structures. Traditional methods, which are labour-intensive and involve preparing and testing samples in the form of cubes or cylinders, can cause delays and uncertainties.

To enhance both efficiency and accuracy in determining concrete quality, our Real Estate segment has embraced innovative technology by adopting wireless maturity sensors, aligning with the American Society for Testing and Materials (ASTM) C1074 standard. These sensors, embedded directly within the concrete, monitor the hydration temperature history, a key indicator of strength development.

This advanced method delivers continuous, real-time insights into the concrete's maturity, providing a reliable basis for making informed decisions about the appropriate timing for subsequent construction activities. By integrating wireless sensors, we can optimise construction schedules, maintain rigorous quality standards, and mitigate risks associated with premature building activities. This technology not only improves the safety and efficiency of our projects but also plays a crucial role in enhancing the long-term durability and structural integrity of our constructions.

Embracing technological advancements, our projects integrate Robotic Process Automation (RPA), AI, and the Internet of Things (IoT) to redefine the standards of living and construction efficiency. These technologies streamline operations, enhance productivity, and ensure timely and cost-effective completion of projects with minimal errors.

We employ Building Information Modelling (BIM) as a core technology across our developments. BIM develops a collaborative environment among all stakeholders involved in a project, enhancing communication, and facilitating efficient decision-making. Its capabilities in clash detection and resolution significantly improve the design and construction processes, ensuring that every project aligns perfectly with our vision for high-quality, technologically advanced, and secure living spaces.

By integrating these sophisticated tools, we not only meet but exceed the modern homeowner's expectations, providing an enriched living experience that leverages technology for comfort, convenience, and sustainability.

At CTIL's Real Estate segment, our dedication to sustainability is woven into every aspect of our business operations. We prioritise the use of locally sourced materials to reduce transportation emissions and implement rigorous waste management practices to ensure responsible disposal and recycling during construction.

Our designs focus on energy efficiency, maximising the use of natural light and ventilation to reduce reliance on artificial climate control systems, which not only conserve energy but also ensure healthier living conditions, embodying our commitment to environmental stewardship.

Water conservation is a critical aspect of our sustainability strategy. Our properties are equipped with state-of-the-art wastewater treatment facilities that recycle water for irrigation. Moreover, we have installed water-saving fixtures like low-flow toilets, which significantly reduce water usage per flush, aerated faucets that mix air with water to maintain pressure while using less water, and water-efficient showerheads that optimise water flow without compromising the showering experience. Additionally, sensor-operated faucets are installed to minimise water wastage by ensuring water is only dispensed when necessary. We also support sustainable water management through rainwater harvesting systems that contribute to reducing our dependence on water supplies, showcasing our commitment towards water stewardship.

Renewable energy solutions, including the installation of solar panels for street lighting and water heating, play a pivotal role in our energy strategy. These help to cut carbon emissions and reduce our reliance on non-renewable energy sources. Moreover, we strive to integrate biodiversity conservation into our operations by complying with all relevant state and national laws, preserving natural habitats, indigenous species, and ecosystems, ensuring the green cover, protecting existing native trees and taking steps to safeguard endangered & vulnerable species of flora and fauna through our biodiversity policy. This not only helps in carbon sequestration but also provides residents with scenic verdant areas to relax and rejuvenate.

Our commitment to environmental stewardship is evident throughout our construction and operational practices, rigorous waste management practices which ensure responsible disposal and recycling during construction, minimising environmental impact, our emphasis on renewable energy, energy efficiency, leveraging natural light and ventilation to reduce reliance on artificial climate control systems, along with state-of-the-art wastewater treatment facilities and rainwater harvesting systems. Furthermore, we are also committed to biodiversity conservation by preserving natural habitats and safeguarding endangered species.

Utilising Ground Granulated Blast Furnace Slag (GGBS) at Birla Niyaara and Alokya and its Impacts

We have incorporated ground granulated blast furnace slag (GGBS) into our concrete mix at Birla Niyaara & Alokya. GGBS, a by-product of the iron-making process, serves as an exemplary supplementary cementitious material (SCM) that significantly enhances the ecological and structural integrity of our constructions.

The integration of GGBS in our concrete formulations aligns with our strategic focus on sustainable development. By substituting a portion of Portland cement with GGBS, we achieve concrete with superior strength and durability, effectively reducing the likelihood of cracking, shrinkage, and permeability. This not only extends the lifespan of our structures but also diminishes maintenance needs, translating into considerable cost savings over the life cycle of the buildings.

Moreover, the use of GGBS plays a crucial role in our environmental stewardship efforts. Annually, we have successfully prevented the emission of approximately 1,805 metric tons of CO2 by opting for GGBS as a sustainable alternative in our concrete production. This practice not only diverts significant amounts of industrial by-product from landfills but also promotes resource conservation by integrating these materials back into the construction cycle, thereby fostering a circular economy.

Advancing Sustainable Buildings

CTIL's real estate segment pioneers sustainable residential and commercial buildings that epitomise our commitment to environmental stewardship and social responsibility. From inception to completion, our projects integrate innovative design, advanced technologies, and responsible construction practices to minimise environmental impact and enhance occupant well-being. Through attention to detail, we align our development with the Indian Green Building Council (IGBC), incorporating features such as passive design principles, high-performance insulation, and renewable energy solutions to reduce carbon emissions and promote sustainable living.

Our flagship projects Birla Centurion and Birla Aurora are platinum-certified, highlighting our focus on building safe, sustainable, and superior experiences. Notably, Birla Centurion sets a new standard with its 150 KLD ZLD system, a testament to our dedication to water conservation and environmental responsibility. These achievements, coupled with our integration of rigorous environmental standards as recognised by the IGBC certifications, showcase our efforts in promoting energy efficiency, water conservation, and environmental stewardship.

Project/Property-wise List of our Green Building

| Project Type | Project Name | Certifications | Location |

|---|---|---|---|

| Residential | |||

| Birla Vanya | IGBC Gold Pre - Certification | Mumbai | |

| Birla Navya | IGBC Gold Pre - Certification | Gurugram | |

| Birla Niyaara | LEED Platinum Pre - Certification | Mumbai | |

| Birla Tisya | IGBC Platinum Pre - Certification | Bengaluru | |

| Birla Alokya | IGBC Gold Pre - Certification | Bengaluru |

Pulp and Paper Manufacturing

CTIL's Pulp and Paper segment operates from a large manufacturing plant in Lalkua, Uttarakhand, covering 396 acres, with an annual production capacity of 4.81 lakhs MT.

We pride ourselves on being one of the most responsible manufacturers in the country, pledged to environmental care and community aid.

By extensively utilising recycled materials and agro-based inputs like bagasse, we significantly lower our ecological footprint. Our commitment to the effective utilisation of cutting-edge technologies and sustainable manufacturing practices enhances operational efficiency and product quality, reinforcing our leadership in the sector and our dedication to deliver superior value to our customers and stakeholders.

We focus on enhancing product quality, operational efficiency, and sustainability within our Pulp and Paper operations. The division prioritises the use of eco-friendly materials like bagasse and recycled paper, and champions initiatives like social forestry to support environmental sustainability. Innovation is key, with efforts to develop new, sustainable products such as ultra-soft tissues and eco-friendly packaging solutions. Integrating World Class Manufacturing (WCM) practices, including the Kaizen initiatives, are central to the segment's operations, ensuring continuous improvement in productivity, quality, and environmental stewardship.

Our primary areas of focus align closely with the key principles of sustainable development and responsible business practices, which are crucial for optimising resource efficiency and minimising our environmental footprint. By concentrating on the sustainable sourcing of raw materials, the implementation of advanced recycling processes, and the adoption of renewable energy sources, we aim to reduce our ecological impact while enhancing operational efficiency. Our commitment extends to social responsibility, where we engage in community development and ensure the well-being of our workforce. Together, these efforts not only create value for our business but also contribute positively to society.

Our Focus Areas

Maximisation of Forest Value Through Sustainable Forest Management

Impact Oriented Society through Recycling

Commitment to Superior Quality Standards

Continuous Improvement in Manufacturing Processes

Utilisation of Renewable Energy Resources in Industrial Operations

Maximisation of Forest Value through Sustainable Forest Management

Efficient and sustainable forest management features in every aspect of our Pulp and Paper operations. By implementing responsible raw material sourcing strategies and adhering to strict environmental standards, we effectively manage the forest covers. Through our Social Farm Forestry initiative, and partnerships with various stakeholders including NGOs and community groups, we ensure a steady, sustainable supply of pulpwood. These efforts not only guarantee the continuity and quality of our material supply but also enhance its cost-effectiveness.

Building an Impact-oriented Society through Recycling

Our approach to incorporate recycled paper as a raw material in pulp production processes emphasises our commitment to sustainability and environmental protection. By reusing recycled paper, we significantly reduce our reliance on virgin wood fibre, thereby conserving natural resources and minimising environmental impact. This strategic initiative not only aligns with global sustainability goals but also contributes to mitigating climate change by reducing carbon emissions associated with traditional pulp production methods. Furthermore, by adopting circular economy principles, we demonstrate our dedication to responsible resource management and set a commendable example for the pulp and paper industry.

Commitment to Superior Quality Standards

Our commitment to quality is evident at every stage of production, the meticulously crafted Standard Operating Procedures (SOPs) ensure the seamless integration of Quality Assurance (QA) and Quality Control (QC) across every facet of our operations. From rigorous checks and verification of raw materials to real-time monitoring of process control parameters to cutting-edge Distributed Control Systems (DCS), we leave no stone unturned in upholding quality standards. Our state-of-the-art laboratories, strategically positioned within each section and department, guarantee the precision and integrity of final products and components. In essence, our focus on quality encompasses every aspect of our operations and services, ensuring that we deliver the highest quality products to our customers.

Continuous Improvement in Manufacturing Processes

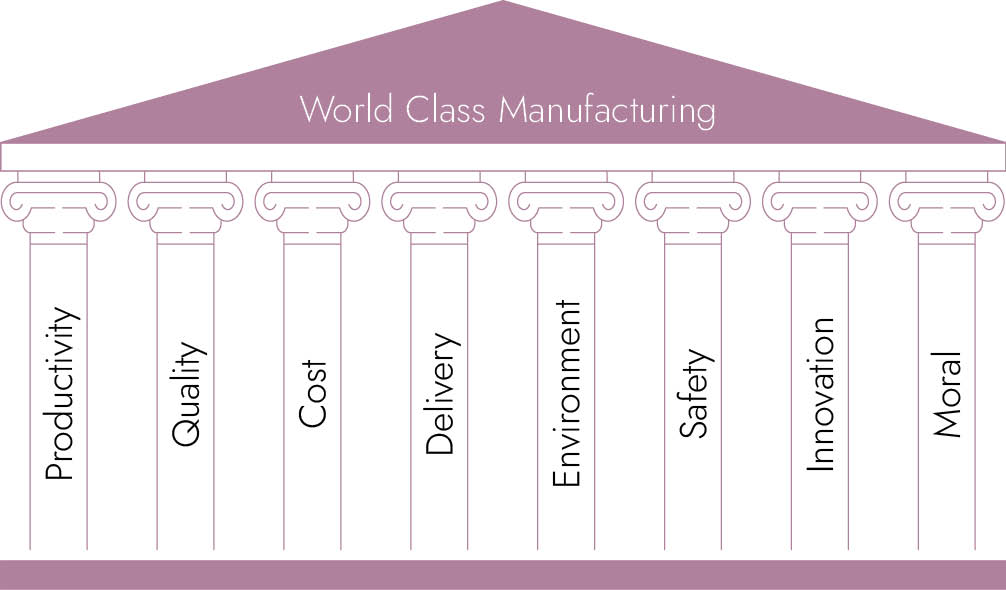

At our Paper and Pulp segment, WCM principles are at the heart of our commitment to operational excellence. Our approach is built around the continuous improvement framework known as PQCDESIM— Productivity, Quality, Cost, Delivery, Environment, Safety, Innovation, and Morale. This robust framework guides our operations, enhancing efficiency and competitiveness. A key component of our strategy is the Kaizen programme, which has successfully embedded a culture of continuous improvement across our Company. This initiative encourages broad participation and innovative problem-solving at all levels, significantly exceeding its targets since inception.

Utilisation of Renewable Energy Resources in Industrial Operations

Our approach to energy management highlights our devotion to sustainability by significantly increasing the use of renewable energy sources, such as solar power, and bioenergy. By integrating energy produced from solar power plants and biomass, we have enhanced our renewable energy portfolio, reducing reliance on non-renewable sources, and supporting the global transition to a low-carbon economy. The extensive use of biomass, which includes wood bark, perul, pith & CMG and black liquor, has already generated significant energy outputs, contributing to our overall energy efficiency, generating 4,982.35 MJ of energy in FY 2023-24.

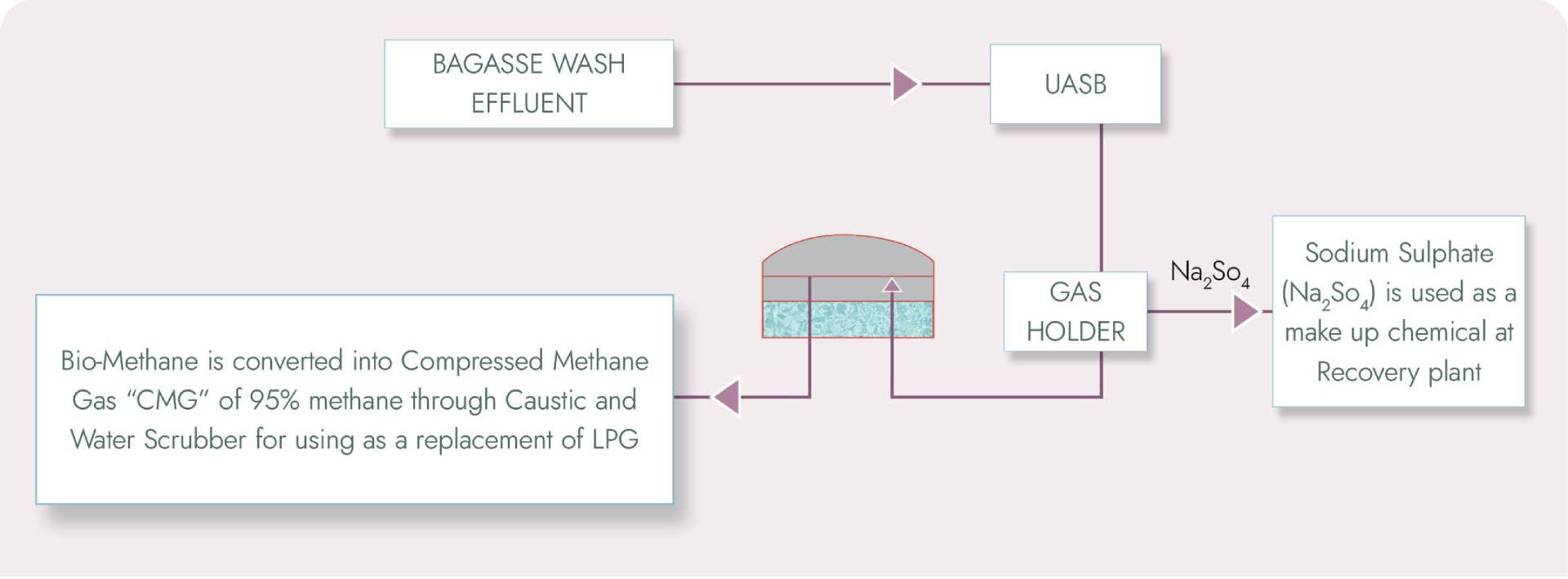

Innovative Bio-gas Production from Efficient Wastewater Management

504 MT

Substitution of LPG at tissue plant in FY 2023-24

426 Kg

In-house Sodium Sulphate produced in FY 2023-24

In pursuit of sustainable solutions, CTIL's Pulp and Paper segment implemented an innovative approach to reduce reliance on conventional energy sources. By leveraging advanced green technology, we efficiently treat high Chemical Oxygen Demand (COD) wastewater from bagasse-based paper production, converting it into valuable biogas. This biogas, primarily consisting of methane, is then purified, and compressed into Compressed Methane Gas (CMG), serving as a viable substitute for traditional Liquefied Petroleum Gas (LPG). Furthermore, the process yields sodium sulfate as a by-product, which is repurposed as a makeup chemical at the recovery plant.

Utilising CMG as a substitute for LPG and sodium sulfate as a by-product not only reduces the Company's carbon footprint but also showcases our efforts in resource optimisation. This strategic initiative not only aligns with our sustainability goals but also sets a commendable example for the pulp and paper industry.

Diverse Product Offerings

Our extensive expertise manifests in our diversified product offering designed to meet both traditional and specialised needs across various industries. We excel in producing fine writing and printing paper, which includes specialised options such as MICR cheque paper for banking needs, high-quality Maplitho (surface size-paper) for offset printing, and versatile copier paper for daily office use. Our Overlay Tissue caters to specific industrial requirements, emphasising our capability to serve niche markets.

In addition to these, we produce a range of virgin fibre grade soft tissues, which are crafted from pure wood pulp to ensure superior softness and absorption. These include Facial Napkins, Kitchen Towels, Toilet Tissues, and Carrier Tissues, designed for both household and commercial use. Our leadership extends into the packaging sector with our Multilayer Packaging Board offerings, comprising of Folding Box Board (FBB), Solid Bleached Sulphate (SBS), and Cup Stock grades, widely used in food packaging and other applications.

Our commitment to sustainability is highlighted through our innovative Century Green Pulp, an eco-friendly product derived from responsibly managed resources. This unique pulp variant is utilised in producing environmentally friendly tableware, reducing dependency on non-renewable materials, and offering a sustainable alternative in consumer goods. This diverse range of products not only reflects our commitment to meet the evolving demands of our global clientele.

Empowering Growth through our Key Products

We focus on driving growth with our key products, using advanced engineering and technology to meet both global and local market needs.

Writing and Printing Paper

We specialise in a variety of writing and printing papers tailored for notebooks, envelopes, and industrial applications. Recently, we have expanded our offerings to include unbleached Kraft (Hi BF) paper, specifically designed to cater to the burgeoning demands of the e-commerce sector.

Tissues

As one of leading tissue paper manufacturers, we manufacture a wide range of tissues, including OBA-free tissue products from 100% virgin pulp. Our offerings include paper napkin tissues, bathroom tissue rolls, kitchen towels, and facial tissues. All our tissue products are FDA certified and elemental chlorine-free, ensuring they meet the highest standards of safety and quality, making them among the best in the Indian market.

Multilayer Packaging Board

Our production facilities deliver premium quality packaging solutions such as Folding Box Board (FBB), Solid Bleached Board (SBB), Solid Bleached Sulfate (SBS), and various backboards, including poly-coated, uncoated, and grey back. These boards are highly sought after in the FMCG, pharmaceutical, and food industries for their superior protection and presentation capabilities.

Speciality Products

Our commitment to environmental sustainability is exemplified by our Century Green pulp, used in eco-friendly tableware products. This innovative product is derived from responsibly managed resources, reflecting our dedication to reducing environmental impact.

Through these key product categories, we not only meet the diverse and evolving needs of our customers but also drive sustainability, quality, and innovation in the Pulp and Paper segment. Each category represents our advanced manufacturing capabilities and strategic vision, ensuring that we continue to be a leader in the market and a trusted partner in sustainable manufacturing.

Enabling Quality Production

Through ongoing investments in R&D, along with advancements in technology, we have strategically utilised sustainable raw materials such recycled paper to produce pulp. This approach has not only enriched our product offerings with innovative, eco-friendly solutions but also enhanced the quality of our existing product line-up.

100% Virgin Pulp

CTIL's Pulp and Paper segment exclusively utilises 100% virgin pulp in its production processes, particularly for tissue products. This choice guarantees superior strength, durability, and purity in all our tissue products.

Production of OBA-Free Paper

Our commitment to reduce chemical use extends to producing Optical Brightener Agent (OBA) free tissue products. This approach ensures our papers maintain their natural colour while minimising adverse environmental and societal impact.

Forest Stewardship Council (FSC) Certification

Our dedication to sustainable forestry practices is reflected through our product offerings that include use of Forest Stewardship Council (FSC) certified materials for required products. This prestigious certification ensures that our paper products are sourced from responsibly managed forests, promoting biodiversity, and supporting local communities.

Adoption of Element Chlorine-Free (ECF) Bleaching Techniques

We employ Elemental Chlorine-Free (ECF) bleaching techniques in our paper production to avoid the use of harmful chlorine compounds. This method significantly reduces the potential for environmental pollution and supports our sustainability goals.

By advancing our manufacturing processes and embracing sustainable raw materials, we are not only adhering to global sustainability standards but also actively contributing to the preservation and enhancement of natural ecosystems. This strategic direction ensures our operations support both the environment and our communities, affirming our commitment to responsible industry leadership.

These certifications highlight our commitment to maintain exacting standards in quality, environmental management, and sustainability across our operations.

Certifications for our Excellence in Production

| Certifications | |

|---|---|

| ISO 9001 | Quality Management Systems (QMS) |

| ISO 14001 | Environmental Management Systems (EMS) |

| ISO 45001 | OH&S management system |

| FSC C104223 | Forest Stewardship Council |

World Class Manufacturing (WCM)

At CTIL's Pulp and Paper Segment, WCM is more than a methodology; it is the backbone of our drive towards operational excellence. It is anchored on an integrated management model that prioritises continuous improvement across all facets of our operations. This model ensures that we maintain competitiveness through rigorous focus on quality, delivery, and cost efficiency.

WCM Framework

Our WCM model is structured around eight interlinked pillars, encapsulated by the acronym PQCDESIM—Productivity, Quality, Cost, Delivery, Environment, Safety, Innovation, and Morale. Each of these pillars represents a core area of focus that collectively drives our quest for manufacturing excellence.

Kaizen: Catalyst for Lean Manufacturing

Kaizen is the cornerstone of our culture of continuous improvement. Initiated a year ago, our Kaizen programme was aimed at embedding lean manufacturing practices across the unit, enabling us to reduce costs and enhance operational efficiency. The initial target for the FY 2023-24 was set at 600-700 Kaizens, but the enthusiastic response from our teams led to a staggering achievement of more than 300% of the target.

It involves organising focused events that engage teams from various levels of our Company. These events are specifically designed for a problem-solving environment and where systematic approaches to challenges are the norm. The inclusivity of the programme ensures that suggestions and improvements are sourced from everyone across the hierarchy, from management to the shop floor workers.

Training and Empowerment through One-Point Lessons (OPLs)

A key component of our Kaizen initiative is the implementation of One-Point Lessons (OPLs). These lessons are targeted at enhancing the understanding of machinery operations among employees. OPLs provide crucial information about critical machines, including operational do's and don'ts, assembly, and layout details. These lessons are circulated to each operator, ensuring that every team member is equipped with the knowledge to operate safely and efficiently.

Recognition and Incentivisation

To sustain the momentum of the Kaizen initiative, the segment conducts quarterly awards that recognise the best Kaizens and the plants that have submitted the most improvements. The selection process is meticulously designed to avoid biases, with nominations reviewed by a committee composed of cross-functional heads. Each Kaizen is evaluated against the PQCDESIM criteria and rated on a scale of 1-5. The awards not only celebrate achievements but also plays a crucial role in refining our Kaizen management system.

Enhancing Tissue Production Efficiency: A Case Study in Operational Excellence

In line with our World Class Manufacturing (WCM) principles, particularly focusing on Productivity and Quality, a pivotal modification was undertaken in one of our key tissue production lines. This initiative, which began as a Kaizen project that later won the quarterly "Best Kaizen Award," aimed at optimising machine operations through advanced algorithm adjustments and comprehensive machine parameter analysis.

Operational Improvement: The modification involved a detailed re-evaluation and recalibration of the tissue machine's operational algorithm. This strategic adjustment allowed for a 20% increase in machine speed, enhancing throughput without compromising product quality. The process also included a rigorous examination of existing machine parameters and the implementation of real-time monitoring systems to ensure optimal performance continuously.

Impact on Production: These enhancements led to an increase in the annual tissue output by 1529.5 metric tons. Moreover, the operational efficiency gained through this initiative significantly reduced production costs. These savings are fundamental in reinforcing our competitive edge in the market, aligning with our overarching goals to control cost and maximise resource utilisation.

Team Engagement and Morale: A critical aspect of this project was its impact on team morale and competency. The successful modification of the production line not only demonstrated our capability to innovate and improve but also played a crucial role in skill development for our workforce. The project engaged multiple levels of our operational team, fostering a sense of accomplishment and enhanced ownership over the production processes.

This case study is a testament to our promise to enhance efficiency and productivity through innovative practices in the pulp and paper industry and effectively embrace benefits of lean methodology through Kaizen.

Streamlining Paper Production: Advanced Automation in Copier Conversion Lines

We identified the necessity for technological advancements in our paper conversion processes. Previously hindered by outdated automation and manual interventions, the conversion lines faced challenges in maintaining the pace and quality required to meet market demands effectively.

Technological Enhancement: To address these challenges, we implemented a dual approach, upgrading the existing cutter line and installing a new, state-of-the-art LineOmatic cutter. The upgrade of the existing line involved enhancements to machine automation that rectified issues related to size variation and increased operational speed by 150 meters per minute, significantly boosting throughput.

New Installation: The installation of the new LineOmatic cutter, with an annual capacity of 50,000 metric tons, was a strategic move to directly convert large paper reels into A4-sized copier reams. This not only streamlined the conversion process but also ensured higher consistency and quality in the final product.

Operational Benefits: The integration of advanced automation in the conversion lines has led to a notable reduction in workforce requirements and packaging costs. This optimisation has yielded in significant monthly savings, leading to operational excellence and fiscal prudence.

The successful implementation of these technologies sets a benchmark for future upgrades and reaffirms our dedication to continuous improvement across operations through continuous improvement.

Way Forward

As we reflect on our achievements and challenges, the journey ahead for our manufacturing operations is both ambitious and crucial. Embracing a future-oriented approach, we desire to enhance our manufacturing processes through sustainable practices, technological innovation, and efficient resource management. This strategic direction is designed not only to optimise our current operations but to also set a robust foundation for sustainable growth and value creation across manufactured capital. We aim to,

Enhance Sustainable Manufacturing Practices

Prioritise sustainable resource management and expand our social forestry initiatives to become wood positive, securing a sustainable supply of raw materials and contributing to carbon sequestration.

Adopt and Expand Use of Renewable Energy

Increase the deployment of renewable energy in our operations, particularly through the integration of solar energy, biogas, and installation of new recovery boilers.

Commit to Quality and Efficiency

Continue to uphold stringent quality checks through the production process and enhance operational efficiency through technological upgrades, ensuring that all manufacturing processes meet or exceed industry standards.

Advancing WCM

Looking ahead, we are committed to advancing our WCM practices by integrating more sophisticated technologies and methodologies that align with our sustainability goals and operational needs. We aim to not only maintain our leadership in manufacturing efficiency but also set new benchmarks for environmental protection and social responsibility within the industry.